COLD DRAWN SPECIAL PROFILES

CAESA has a long experience in the cold drawing of special profiles in steel.

CAESA is specialized in the steel transformation by cold drawing since 1946 and has a good command of the requirements of these products.

CAESA currently exports cold drawn special profiles worldwide.

The CAESA team supports each industrial customer in all the different areas with the objective of offering the best personalized solution.

Definition of the cold drawn profiles

This production process consists in cold stretching the bars by pulling them though hard metal dies in one or several phases, according to the final shape that the customer needs to obtain.

In this process, round steel bars are used as a raw material in different diameters, or also steel wire in coils for smaller shapes.

By traction cold drawing in our drawing benches, we can achieve the final profile shape with tight tolerances, and at the same time, we obtain an optimized rugosity on the special profile surface.

How is the cold drawing process done in CAESA

In order to achieve a cold drawn shape, an initial shaping process of the steel is often needed: a previous hot rolling process is made in our hot rolling lines, where we obtain a first preform that is used for the cold drawing process, in order to achieve the desired final shape. In addition, other intermediate processes are needed such as oven annealing and shotblasting, with the aim to optimize the mechanical characteristics and the surface quality of the material for its later cold drawing. The cold drawn profile in bars is straightened afterwards, and they can be cut to specific standard bar length with a tolerance, or at specific fix lengths, and bundled. Another finish that we can offer for the profiles in bars is to saw cut into pieces to a specific width defined by the customer and we can condition them in containers for later transport.

After over 75 years of experience, we have some good knowledge of many different market demands.

The customer receives a constant follow up as our main target is to achieve the best possible result and offer the highest quality in each process.

In order to be able to analyze your needs, we require the following information:

Drawing of the profile

Steel grade

Year consumption

Uses of cold drawn profiles

This type of special profile is used in several sectors and industrial applications:

+ Automotive + Tools, tooling and hardware + Machinery

+ Logistics and warehousing + Construction, civil works and mining + Sports armament

+ Railway and shipbuilding + Other applications

Cold drawn profiles advantages

The main advantages of the cold drawing are the following:

- Reduction of the effort and the machining times, as a special shape is used from the beginning.

- The steel costs are lower, as the shape of the profile is closer to the final part needed by the customer.

- The customer production scrap is reduced and consequently the rentability is improved.

- It implies lower tooling costs in order to obtain closer dimensions and tighter tolerances, and it is adequate for medium and large series.

- It improves the production capacity as it is not necessary to add machinery and/or tools.

Characteristics of the cold drawn special profiles

- Special sections between 40 and 1.500 mm2 (0,3 a 12 kg/linear meter).

- Maximum width 100 mm

- Alloyed and non alloyed steels

- Tolerance: +/- 0,05 mm

- Straightness: 1 mm/meter

- Rugosity: Ra 3,2

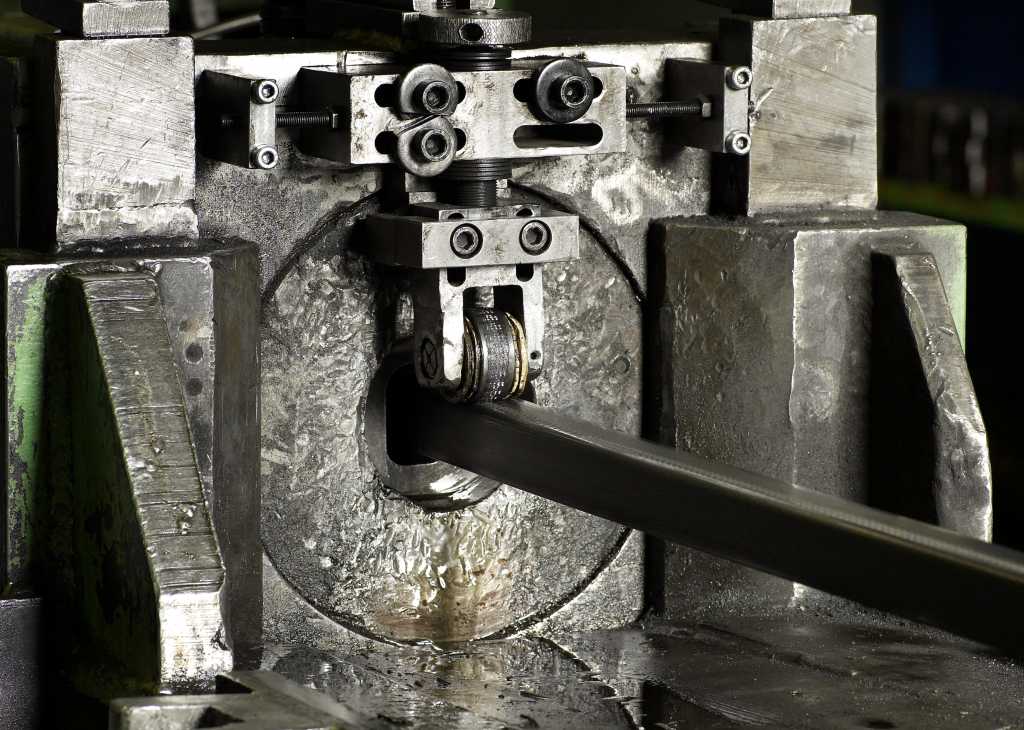

Cold drawing facility- Machinery

Our machinery allows to control the process of the special profile from the beginning until the end, offering a better result and a better quality.

- 1 shotblasting machine

- 2 automatic turning machines for bar ends and chamfers.

- 1 induction rolling facility with two passes online.

- 1 rolling machine for cold processing.

- 2 cold drawing benches with a power of 120 metric tons.

- 1 combined facility for drawing + straightening + cutting profile diameters up to 16 mm.

- 1 friction press of 150 tons.

- 1 furnace for heat treatment.

- 2 saws for bundle cutting.

- 3 multidisk saws for cutting in pieces.

- 1 straightening machine.

Additional processes to accomplish cold drawn profiles

In order to achieve a special cold drawn shape there is often a previous transformation process of the standard steel necessary through a hot rolling process in our production lines where a preform is created that serves as a base for the later cold drawing in order to get the final wished shape.

Also other additional intermediate processes as the shotblasting and/or the annealing are required in order to optimize the surface quality and the mechanical characteristics of the material for the later cold drawing step.

The cold drawn profile is then straightened and cut at specific lengths with a tolerance or at fix lengths upon demand and packed with plastified packaging or wooden boxes.

There is also the option that the profiles could be saw cut in pieces at the determined with by the customer and conditioned in containers for the shipment.

We are producers of cold drawn special profiles

We know in detail the requirements of the cold drawn profiles with the most innovative techniques to achieve the best results in cold drawn steel.

We offer our products at domestic level and abroad.