Caesa, family owned company with international view

We produce hot rolled and cold drawn special profiles in steel according to the customer’s drawing and technical specifications. We are the one of the main players in the market due to our experience of more than 75 years and the flexibility we offer in our processes. We adapt to each customer and their requirements.

We produce special profiles since 1946

in Barcelona as a lamination workshop, created by D. Timoteo Pomés. The main activity was re-rolling car springs from scrapped truck springs, pieces that were difficult to find after the Spanish Civil War.

The Hamsa tool steel company merges with Caesa. From there, they begin to laminate blade profiles for the body and printing industry.

at La Llagosta, a company specialized in cold finishing, turning and polishing.

Incluyendo el calibrado de barras y perfiles especiales para la industria del automóvil. Además de pletinas y cuadrados en todo tipo de aceros, incluyendo inoxidables y aceros de alta velocidad.

Caesa, initially located in Hospitalet de Llobregat, is acquired by the Pascual family.

The company moves to Caldes de Montbui to expand and modernize the facilities.

The firm Multifus is created to carry out the machining of semi-finished shafts starting from calibrated bars.

The sector for calibrating special profiles from La Llagosta is transferred to the Caesa plant.

Nowadays CAESA counts with a well equipped production plant, with a stable team and the biggest commitment is to offer quality products and the best service to their clients.

We work for all type of industries

Automotive

Tools, tooling and hardware

Machinery

Logistics and warehousing

Rail and naval sector

Construction, civil works and mining sector

Sport armament

Several applications

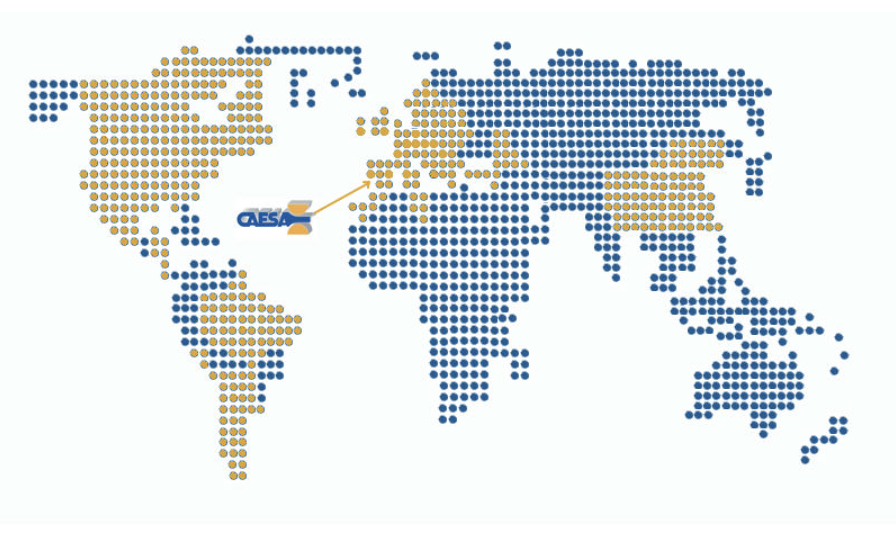

Worldwide presence

We are in the metropolitan area of Barcelona, close to the harbor, the airport and all the main highway network. CAESA has a big international projection due to its long experience in export.

We are a medium sized company and offer a great flexibility and fluent communication to our customers as well as suitable delivery times adapted to the different projects.

Facilities in Barcelona

Caesa has a long experience in the production and export of the products, therefore we know the global markets in detail. We also work closely with a selection of approved first level suppliers to ensure reliable deliveries.

Due to our wide presence, we can communicate in an effective way. We search logistical solutions depending on the needs and the destination of the products of our customers, and many of them are international groups.

We take part in important fairs and association

We regularly participate in fairs. We present some of them. We participate in activities from associations such as Plametall, Acció or Cambra de Comerç de Barcelona.

Tube & Wire Fair

Hannover subcontracting fair

Midest Fair

Automechanika Fair

Bilbao subcontracting fair

AFMEC

We are certified

Our company is IATF 16949, ISO 9001 e ISO 14001 certified by Bureau Veritas. Thanks to this, we can be present in multiple customer sectors.

We have high advanced equipment to manage the quality and satisfy our customers through an accurate evaluation, planning, and execution of our systems. Since 1995 we have implemented continuous improvement teams.

We work systematically in the development of new profiles and in the evolution of our production processes. We carry out product feasibility studies to ensure the quality in all the production phases. The needs of the product are identified according to the requirements of each customer.

In CAESA we are engaged with the quality and the environment

In this document we present our quality policy together with our compromise for the environment and the sustainability.